CONTACT

Your personal contact

Do you have direct questions about our foam machines? Talk to your Kurtz contact person!

The basis for processing expandable polystyrene (EPS) is the pre-expansion system. Kurtz pre-expansion systems are the result of consistent implementation of physical processes in innovative machine technology, intensive exchange of experience with users and recommendations of raw material manufacturers - and are flexibly adaptable to any requirement with high economic efficiency and in top quality.

Kurtz Pre-Expanders guarantee a high degree of automation, reliable control and reproducibility as well as a uniformly foamed product. Together with simple operation, they bring calculable economic advantages. Kurtz offers a complete range of continuous and discontinuous pre-expanders in sizes from 0.15 to 3.0 m3 for the processor of thermoplastic foams.

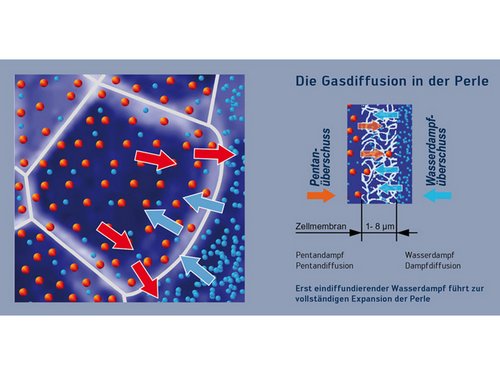

The EPS raw material is conveyed as granules to the pre-expander, where it is heated by means of wet steam. The hot steam softens the polystyrene beads and activates the blowing agent dissolved in them. This evaporates and causes the softened beads to expand. The bulk density can be adjusted by the weight of the raw material and the foamed volume. The EPS beads pre-expanded are then cooled and stabilized in a fluidized bed on an air cushion before being conveyed by blower via a rotary feeder into the silos.

Welding of the end products: During the subsequent intermediate storage, the blowing gas diffuses out of the pre-expanded polystyrene beads and air penetrates. This "packed air" is further processed on an automatic molding machine. To achieve low bulk densities, EPS can also be post-foamed in a second pass.

For expandable polypropylene (EPP), EPP/HP pre-expanders are available for lightweight foaming. This can significantly reduce logistics costs.