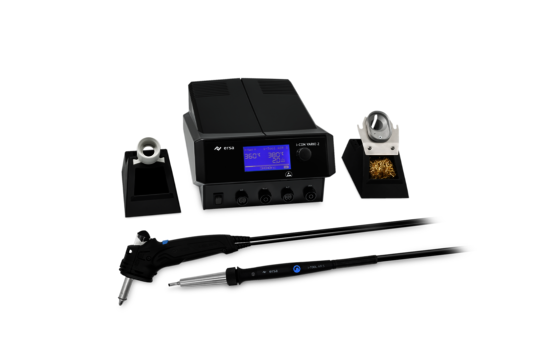

i-CON TRACE: The Missing Link! Ersa IOT Soldering Station

Complete traceability for hand soldering!

1/5

IoT Soldering Station

Ersa i-CON TRACE

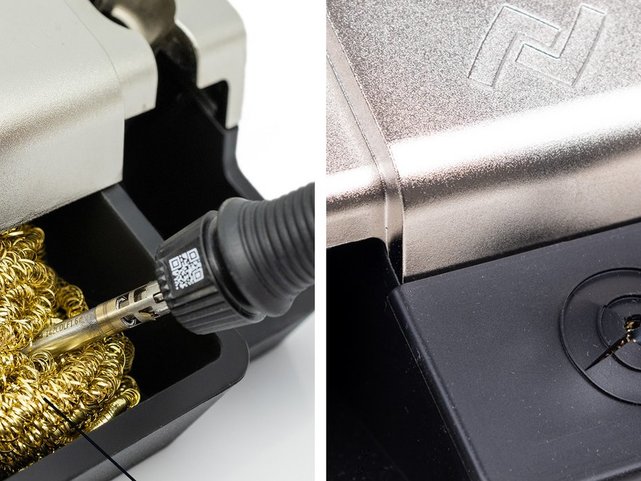

The patented Tip´n´Turn concept enables tips to be changed in record time. The soldering tip can be changed safely in no time at all - with the storage stand or by hand. Impressive: the significantly cooler handpiece of the i-TOOL TRACE - even in continuous operation.

2/5

IoT Soldering Station

Ersa i-CON TRACE

Intuitive and safe operation of the i-CON TRACE with the Ersa TRACE APP via WLAN. Set and display all parameters on any number of soldering stations. For iOS and Android. In real time. With password protection

3/5

IoT Soldering Station

Ersa i-CON TRACE

Unique operating concept including mobile APP control: GREEN MEANS GO. If all conditions for the assigned soldering task are met, the LED interface of the i-CON TRACE literally gives the green light and the user can start the soldering process

4/5

IoT Soldering Station

Ersa i-CON TRACE

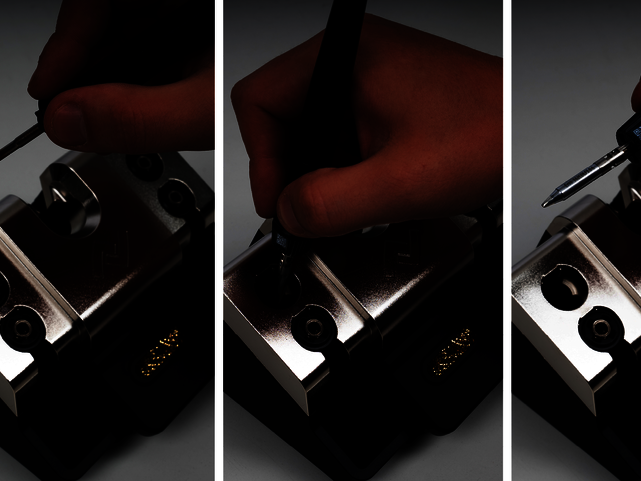

Gentle cleaning of the soldering tip with dry cleaner and optional splash guard for more cleanliness at the workplace

5/5

IoT Soldering Station

Ersa i-CON TRACE

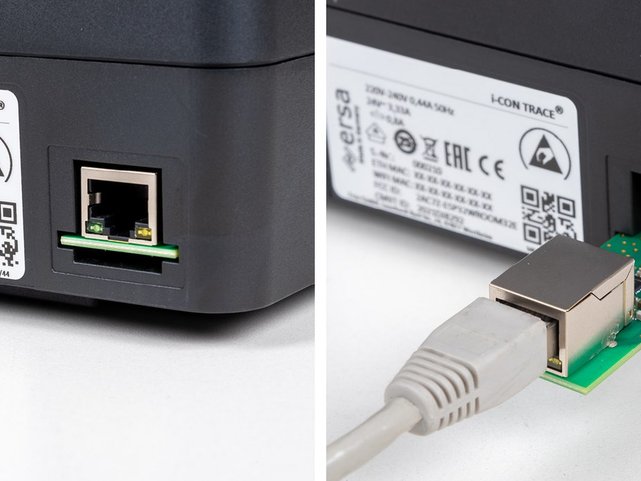

Sets standards in terms of connectivity and operating concept: i-CON TRACE with WLAN and LAN adapter that can be retrofitted at any time

Highlights i-CON TRACEErsa IOT Soldering Station

- Increased process reliability by presetting the parameters and documenting the process data

- Increased productivity and soldering quality thanks to particularly fast and safe Tip'n'Turn soldering tip changes

- Highest precision and excellent reliability

- Significant cost savings thanks to separately replaceable soldering tips

VideosErsa i-CON TRACE

i-CON TRACE FeaturesIoT Soldering Station

Top functionality for networked soldering

More than you expect. And surprisingly affordable. Fast heating, precise temperature control, and outstanding performance and functionality for industrial networked soldering characterize the i-CON TRACE. An invaluable bonus on top: low purchase price and low follow-up costs thanks to the use of separately replaceable soldering tips.

Perfect connectivity

WLAN and expandable network card with the free ERSA TRACE COCKPIT software provide unprecedented connectivity: i-CON TRACE can be connected to a Manufacturing Execution System (MES) with individually configured settings. This means seamless integration of the i-CON TRACE into networked production processes which are already controlled by an MES.