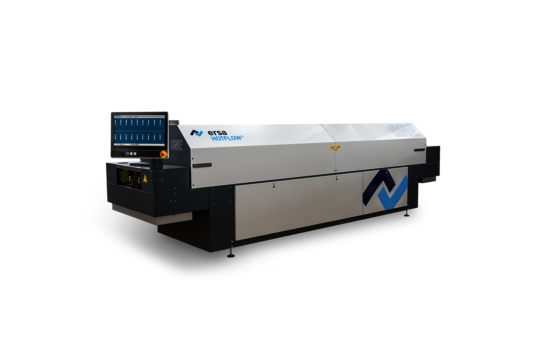

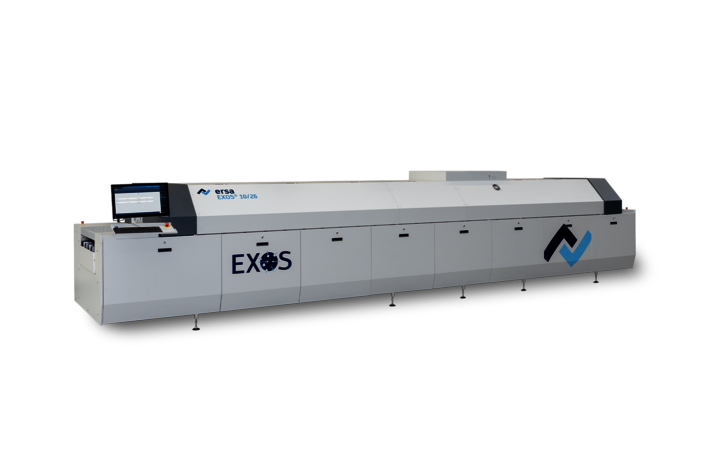

Exos 10/26: Inline reflow soldering under vacuum Ersa Reflow Soldering

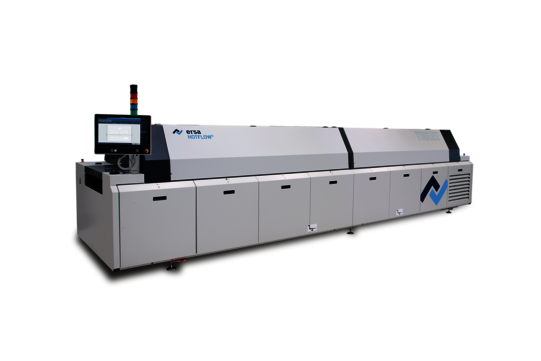

Ersa meets the demands of electronics production for non-porous solder joints - especially for power electronics and high-reliability technology - with the EXOS 10/26, a convection reflow soldering system with 22 heating chambers and 4 cooling zones as well as a vacuum chamber after the peak zone, with which the void rate can be reduced by up to 99%. Thanks to intelligent features, the EXOS 10/26 can produce particularly economically and "void-free".

Ersa Reflow Soldering

EXOS 10/26

Void-free reflow soldering with convection and vacuum.

Highlights EXOS 10/26Ersa Reflow Soldering

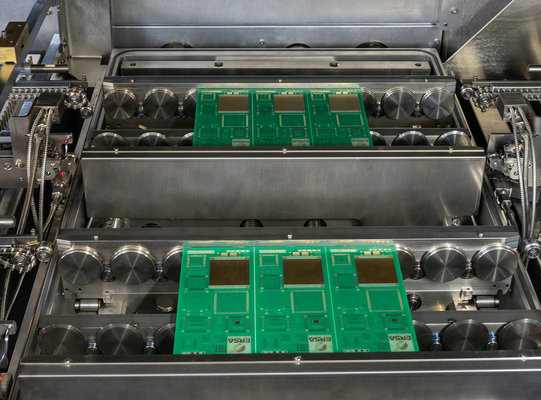

- 4-part transport (infeed, preheating with peak, vacuum, cooling zone), also as dual-track

- Perfect synchronization of assemblies and transitions thanks to sensor-monitored transport, no external infeed module required

- Maintenance-friendly, lubricant-free roller transport in the vacuum module

- Optimum accessibility of the vacuum chamber thanks to lifting unit from above

- Optimum temperature profiles thanks to medium-wave radiant heaters in the vacuum module

- Maximum machine availability thanks to quick removal of the transport unit in the vacuum module

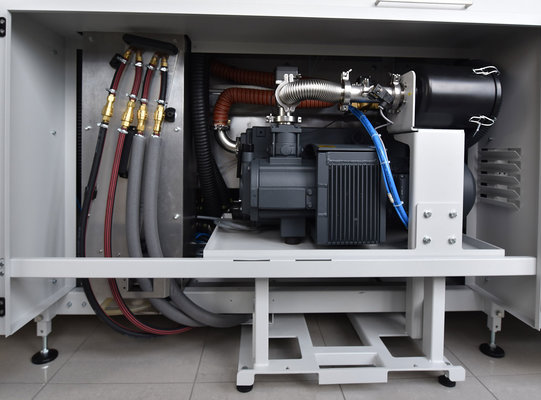

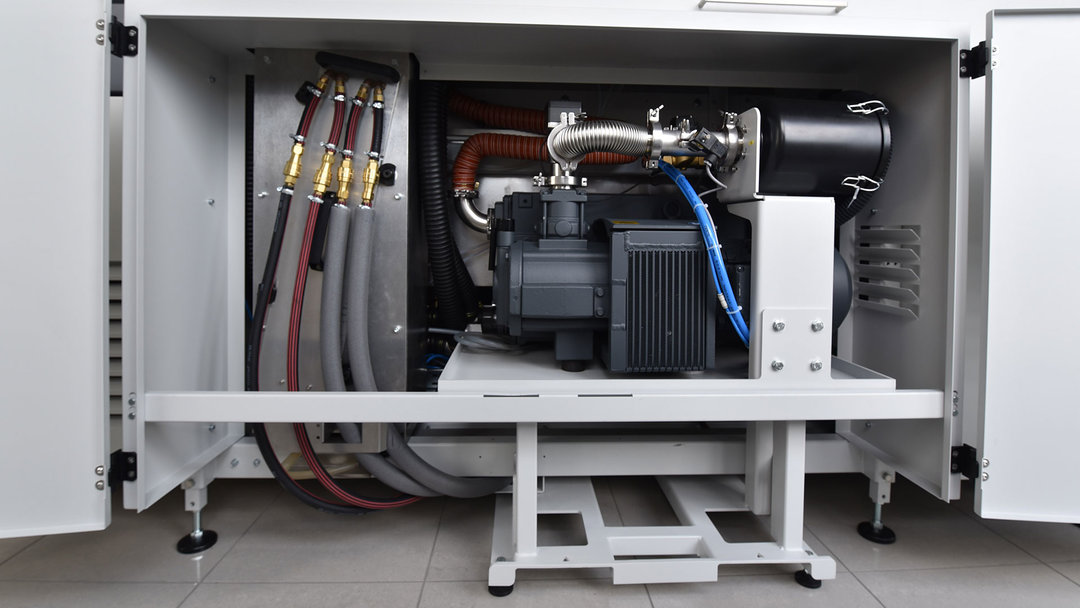

- Partially integrated vacuum pump on separate module carrier for quick maintenance

- Innovative SMART ELEMENTS® cleaning system

EXOS 10/26Ersa Reflow Soldering

EXOS 10/26Ersa Videos

Ersa Reflow Soldering with vacuum – EXOS 10/26

Ersa Success StoriesEXOS 10/26

EXOS 10/26Ersa Reflow Soldering

Technical data

Length:

7,875 mm

Width:

2,195 mm

Height:

1,969 mm

Weight with options:

5,000 kg

Transport System

Working width:

50-630 mm

Working width (center support):

100-630 mm

Passage height:

+/-35 mm

Transport speed:

20-200 cm/min

Pin chain transport:

5 mm support

Process Zone

Inlet:

1,011 mm

Heating zone:

4,545.5 mm

Vacuum zone:

558 mm

Cooling zone:

1,536 mm

Outlet:

730 mm

Heating System

Convection component (except vacuum chamber):

100%

Convection heating modules:

11 top/11 bottom

Preheating:

9 top/9 bottom

Soldering zone:

2 top/2 bottom