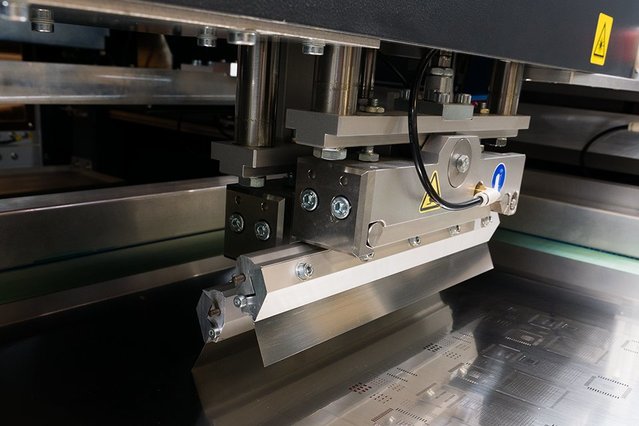

Stencil printer with fully integrated solder paste inspection Ersa Technology

Almost 70% of all process errors in the SMT line can be traced back to stencil printing. Most errors can be eliminated in a cost-saving manner. The Ersa VERSAPRINT 2 printers use modern camera technologies for fast set-up and full-surface solder paste inspection directly in the printer. The intuitive user interface ensures space-saving operation. With "features on demand", the VERSAPRINT 2 can be flexibly adapted to special requirements.