The requirements regarding machine safety are regulated in the Machinery Directive (MRL, Directive 2006/42/EC). As the operator of the plant, you bear full responsibility for operational safety. We will be pleased to support you in identifying potential safety risks.

Because machine safety is Kurtz´s top priority. Our experienced specialists will identify even inconspicuous safety defects on your Kurtz machine. Through an on-site audit, safety problems can be detected at an early stage. In addition, our experts conduct professional safety audits and briefings and, as qualified technicians, are authorized to issue safety certificates according to DGUV.

Standardized interfaces and systems as well as an availability for web browser and smartphones make the platform Kurtz Ersa CONNECT user-friendly and a must-have for your production. With Kurtz Ersa CONNECT, you score in many directions:

The industrial Internet of Things (IoT) is changing our production processes and the entire manufacturing industry. Digitized processes, products and services create new levels of efficiency. Act now and become a pioneer in your field with Kurtz!

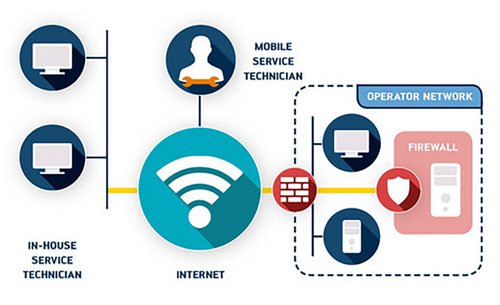

With the help of a VPN connection, we can connect to your machines worldwide and perform error diagnostics and software adjustments. Your advantages: fewer unplanned machine downtimes, more efficient utilization of the machine park and faster service speed.

Do you have questions about our products and services?

Contact us, we are here for you!