For over 50 years, Ersa Wave Soldering Systems have set innovative trends in electronics production, whether in the entry-level class, as compact mid-size machines or as powerful high-end systems that can process XL heavy-duty formats. Whatever your requirements, Ersa POWERFLOW Wave Soldering Systems deliver quality and productivity, providing a safe and energy-efficient foundation for soldering processes.

Wave soldering - the perfect wave! Ersa Technology

Wave Soldering - the classic THT soldering process

With top technology and modular design, Ersa wave soldering systems meet the highest throughput requirements - perfectly tailored to every need and budget. In the maximum expansion stage, PCBs up to 850 mm in length can be soldered and thus used to process server boards for 5G telecommunications. A class of its own, a class of yours!

Wave soldering is an efficient and economical process for the mass production of electronic assemblies using through-hole technology (THT). In contact with the solder wave, many solder joints are formed simultaneously, resulting in the high throughput of this process. In surface mount technology (from the 1980s), it is also used with double wave soldering units to solder SMDs previously bonded to the PCB. In high-performance systems, it is used today, for example, in heat-intensive power electronics applications.

Features Ersa Wave Soldering

Transport

Transport

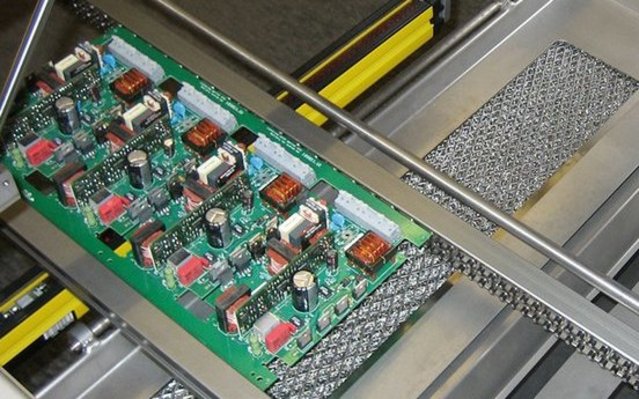

For the transport of PCBs in the soldering system, a choice can be made between systems with solder frame transport or finger transport. The solder frame transport is based on a robust pin chain that is guided in a profile.

The precise PCB tracking enables highest throughput rates, as PCBs or solder frames are transported through the machine with almost no separation distance. Standardized interfaces ensure the smooth transfer of PCBs to and from the connected peripherals.

Fluxing

Fluxing

Spray systems have long been standard for every wave soldering system - here, the flux is applied to the entire surface of the circuit board by means of a spray jet. Ersa also offers numerous innovative solutions around the fluxer, all of which are designed for economy, flux consumption and processing speed. In addition to the "normal" precision spray fluxer, an optional ultrasonic spray head is available for POWERFLOW ULTRA, POWERFLOW PRO and POWERFLOW, which impresses with even lower flux application and even less maintenance.

As an inline selective fluxer, the POWERFLUX expands the Ersa portfolio with another system that revolutionizes THT component processing electronics manufacturing - with precise and defined flux application in the smallest areas, applied at the solder joint as dots or in paths. The wetted area can be as narrow as 2 mm in diameter - a clear advantage in selective mask soldering that reduces flux consumption by up to 95%.

Preheating

Preheating

The aim of the preheating process is to homogeneously heat the printed circuit board before it is tranported into the soldering module. The aim here is to provide up to 50% of the thermal energy so that the PCB is not shock-heated when it comes into contact with the liquid solder. In the field of wave soldering, a modular preheating concept is used. Convection heaters as well as medium-wave radiant heaters and short-wave infrared heaters are available. These can be variably configured and thus individually adapted to production requirements.

Convection modules show their strengths when heating large, high-mass components on the placement side or when temperature-sensitive components are used that must not be overheated. Medium-wave emitters also support the homogeneous heating of high-mass PCBs, which protects temperature-sensitive components. Short-wave IR emitters transmit the different amounts of energy almost without inertia and are thus ideally suited for mixed production.

Soldering Module

Soldering Module

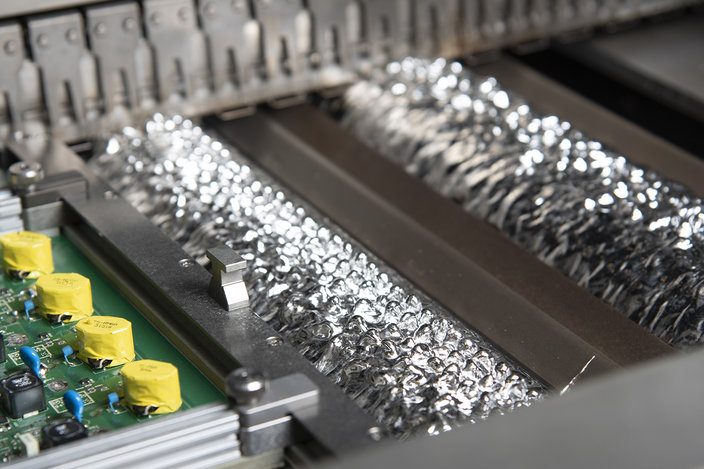

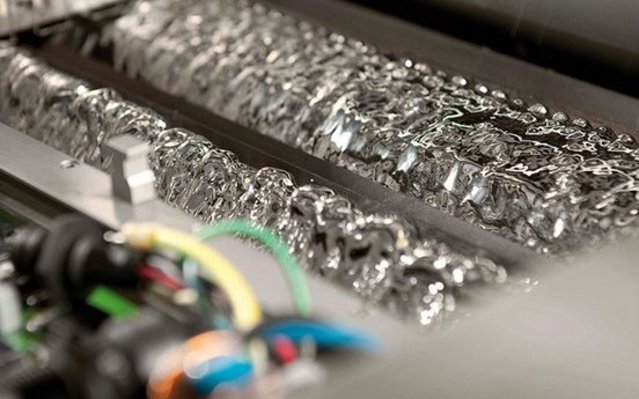

Soldering is performed by a solder wave module with one or two solder nozzles. These correspond to the width of the transport, so that the full surface of the PCB is in contact with the solder. Due to the capillary and wetting forces on the pins, the solder is drawn upwards along the contact to the top of the PCB and solidifies as soon as the solder wave breaks off. The user-friendly soldering unit of the POWERFLOW can be equipped with a wide range of different solder nozzles in order to be optimally prepared for the respective soldering task and to ensure the highest soldering quality.

The easy-to-maintain soldering pots can be conveniently moved out of the system electrically. One example from the Ersa nozzle portfolio is the patented Vario-Wave, which incorporates all of Ersa´s 100 years of soldering experience: this nozzle has outstanding dynamics and very good flow and breakaway behavior. This makes it particularly well suited for masks with deep pockets - as well as for soldering difficult SMD geometries on the underside of the PCB.

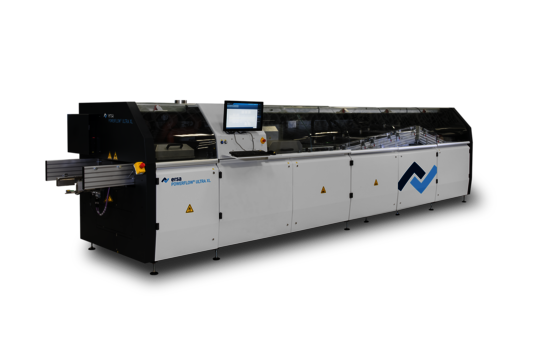

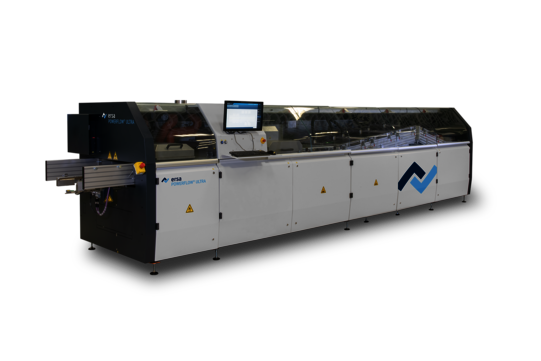

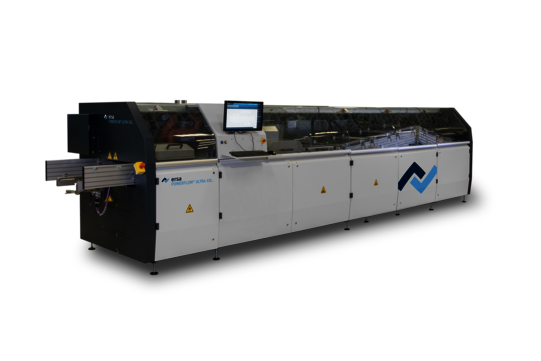

Even at maximum throughput, the POWERFLOW ULTRA XL offers outstanding process stability and future-oriented features with considerable added value.

Compact full-tunnel wave soldering system for cost-optimized wave soldering in a nitrogen atmosphere with award-winning ERSASOFT 5.