The digital services can be accessed via a web browser from any internet-enabled computer or mobile device, regardless of location and device, and increase the reliability and availability of each individual system. They also create transparency and safety – information can be evaluated directly based on data and interpreted efficiently.

The digital machine database integrated in Kurtz Ersa CONNECT provides a convenient, device-independent overview of the entire machine park at a glance. General machine information, hardware and software configurations, operating instructions, circuit and pneumatic diagrams, service documents and documentation are always centrally available to maximize speed and service quality through information transparency. This is linked to an intelligent ticket system for optimizing service processes towards a fast, efficient solution for support cases. All “service cases” are stored and processed centrally in Kurtz Ersa CONNECT and can be sorted by relevance at the click of a button. The clear chat display and the option to add images, descriptions and log files speeds up the solution finding process and increases service efficiency. This saves time and costs and increases the transparency of the support process.

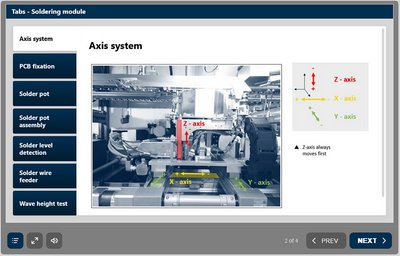

With its integrated e-learning module, Kurtz Ersa CONNECT takes personnel training to the next level and sets the benchmark in the industry. Interactive and modular e-learning courses with 3D animated machine presentations and training videos can be accessed from anywhere and at any time. Learning progress in the globally standardized training material is documented by examinations and certificates. This ensures continuous knowledge transfer – with reduced on-site training requirements and no waiting times for classroom training. The intuitive Kurtz Ersa CONNECT user interface is “future proof” and, thanks to its responsive design, is also ideally positioned for use on mobile devices.

System malfunctions on the customer side must be rectified immediately, as machine downtimes cause high costs. The remote service from Kurtz Ersa CONNECT offers a simple, safe option for remote diagnosis and fast first aid. With the help of the Edge Gateway, Ersa Service can immediately carry out detailed fault finding, diagnosis and troubleshooting. Good to know: Remote maintenance is always carried out via digital switch and only at the customer´s invitation. Kurtz Ersa CONNECT uses common industrial communication standards such as IPC-CFX or MQTT (Ersa standard), so that significantly less effort is required for integration into the customer´s own MES. Whether stencil printer, reflow, wave or selective soldering system, including automation or rework systems – all use the same hardware (Kurtz Ersa GATE) and the same interface. The advantages are obvious: Maintenance, servicing, updates and bug fixing of the interface are only carried out once at a central location. Customer customizations are immediately available for the entire product portfolio. This saves time and reduces costs. The gateway (edge device) ensures a secure and standardized connection between Ersa systems and the outside world – including communication between the cloud, applications and systems. The gateway processes acquired measurement data and information and transmits it securely to the Kurtz Ersa Cloud or optionally directly to the customer´s systems. In addition to the transmission, e.g. of live information for real-time monitoring applications, the gateway offers further options – including remote access in urgent service cases. You too can rely on servitization in your electronics production – with Kurtz Ersa CONNECT!