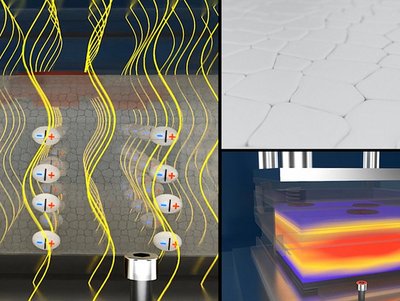

The plastics industry has been looking for alternative manufacturing processes for years. The welding of particle foams via highly efficient radio frequency technology is revolutionizing processing from a sustainability point of view. Compared to the manufacturing process using steam, up to 90% energy can be saved. By eliminating the steam generation equipment previously required, it is possible to significantly improve the CO2 footprint of particle foam manufacturers. Furthermore, the machine is equipped with a fully electric drive. Optimum welds are achieved by using electromagnetic waves in the radio frequency range. In addition, new materials and biodegradable materials can be processed. This was not feasible in terms of process technology due to the high pressures required in standard machines. Top advantage of RF technology: Only by mechanical "shredding" can the particle foam material be returned to the cycle. The WAVE FOAMER shines with a reusability of up to 100%. With EPS in the previous steam process, a maximum of 20% recycled material can be reused.