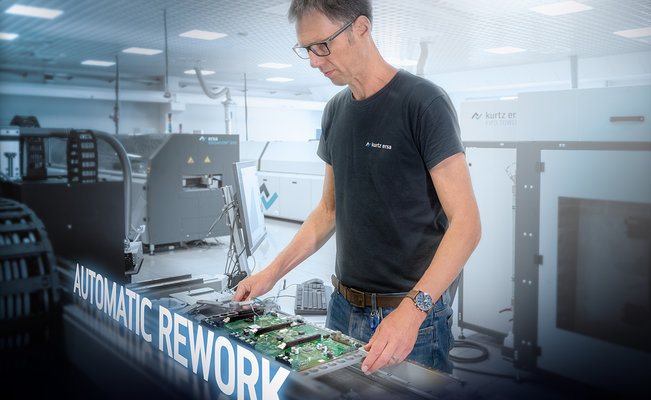

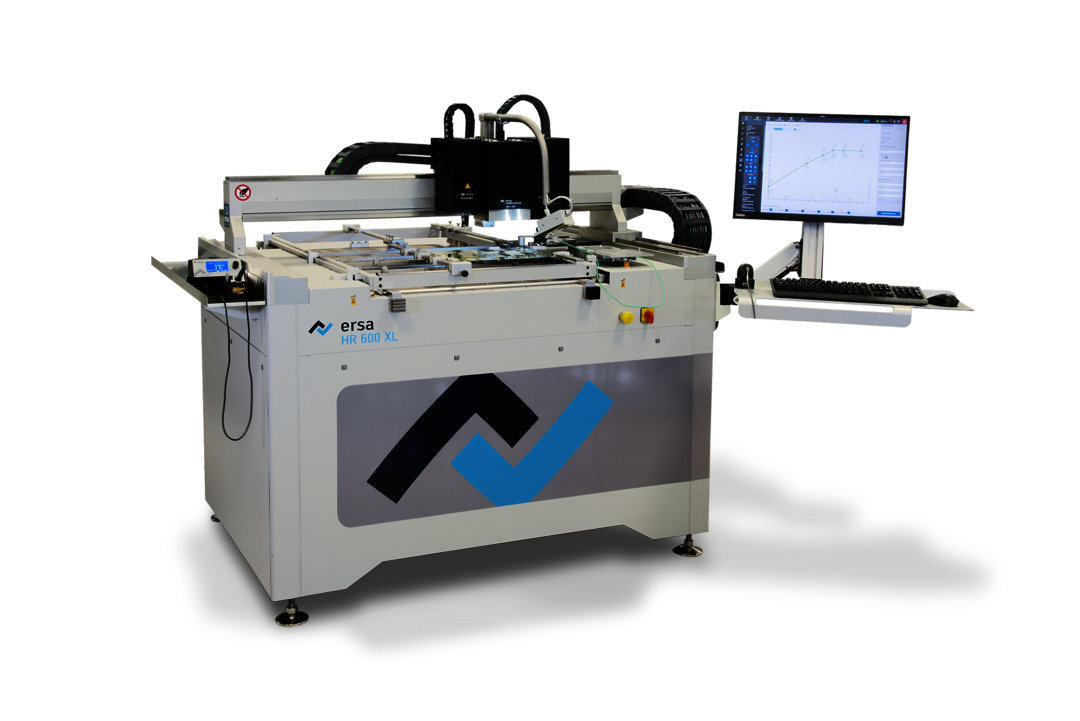

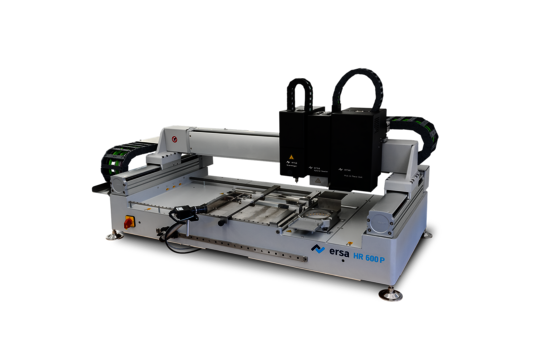

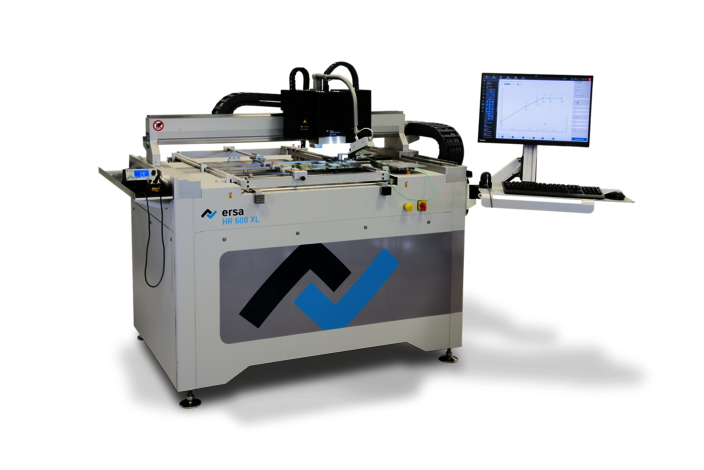

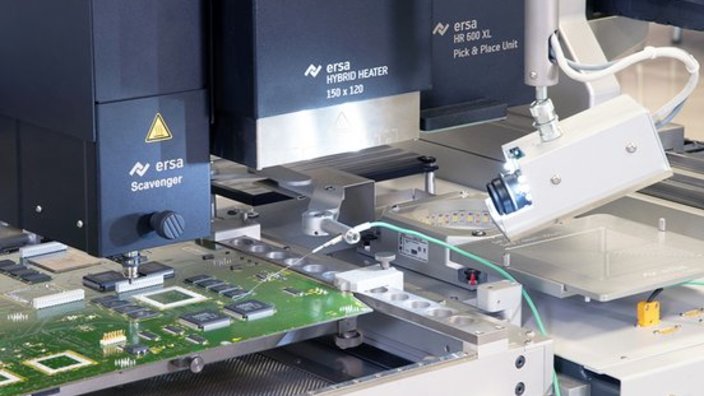

Automatic Rework System Ersa HR 600 XL Ersa Rework

Automatic repair of complex assemblies up to 625 x 625 mm

1/3

Big Board Rework

HR 600 XL: Assembly Repair 'Thinking Big

Reworking instead of throwing away pays off twice - especially with large and expensive assemblies!

It saves enormous costs and helps the environment. The HR 600 XL is up to any challenge! Get in touch with us...

2/3

Ersa Rework

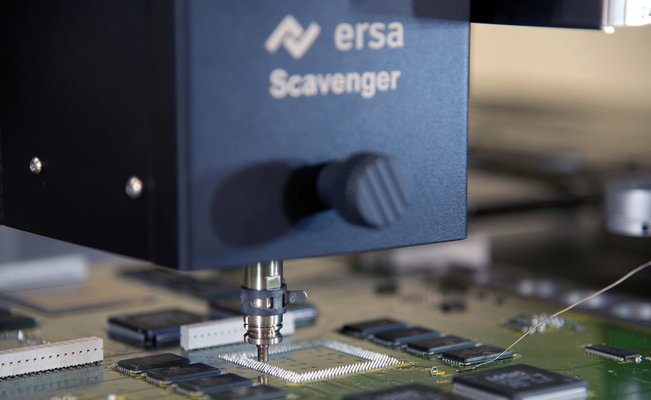

Auto Scavenger - no set-up time!

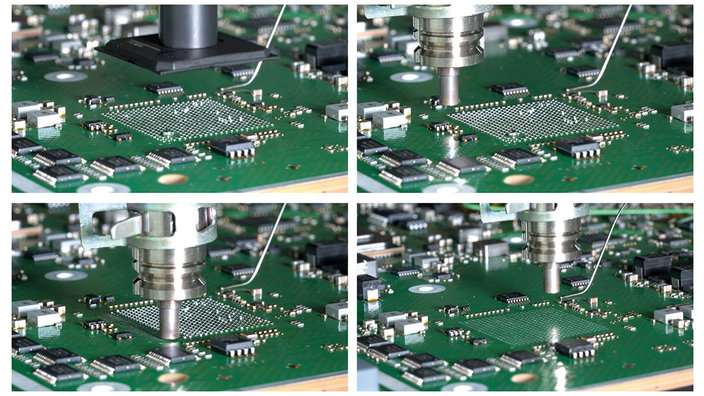

As the Auto Scavenger is a stand-alone module, there is no set-up time for the user. The image collage opposite shows the process (from left to right) from the start with the lifting of a BGA, through the progress of the solder extraction to the complete removal of the residual solder.

3/3

Ersa Rework / Scavenger

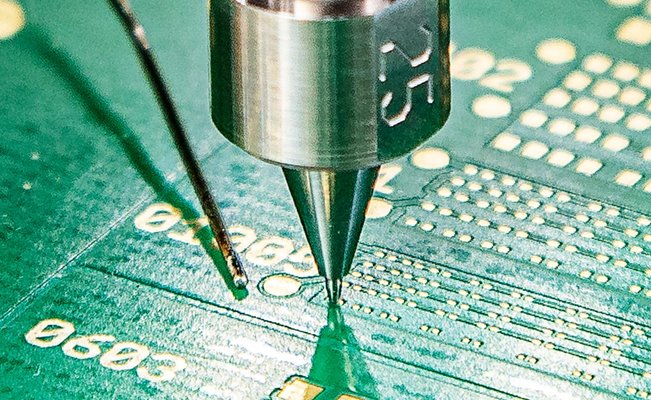

HR 600 XL: Automatic and contactless residual solder removal

After desoldering a component, residual solder must usually be removed. With the "Auto Scavenger" module, there is now a fully integrated functional unit for this - immediately after the component has been removed, the suction nozzle of the Auto Scavenger is lowered over the PCB and the residual solder is removed automatically and without contact.

Highlights HR 600 XLErsa Rework

- Highly efficient, exchangeable heating heads (800 W - 4,800 W)

- Large-area matrix infrared underheating with 25 individual elements (expandable to 50 elements)

- Process monitoring with up to 8 thermocouples

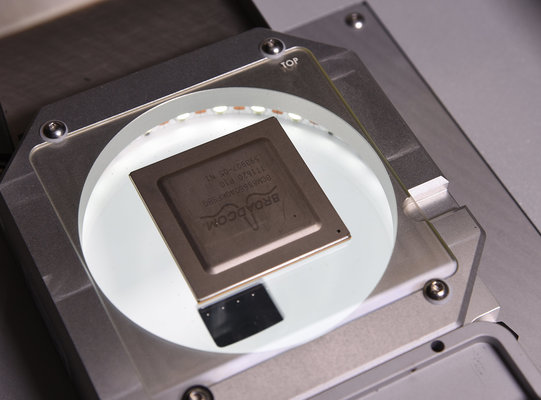

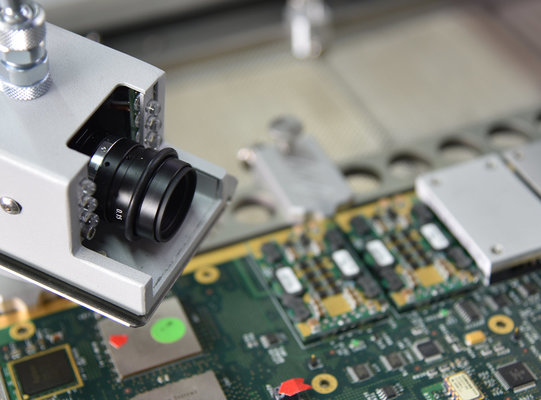

- Automatic and precise component alignment with the aid of image processing

- High-precision, motorized axis system for component placement (up to +/- 0.025 mm)

Advantages HR 600 XLErsa Rework

- Individually configurable system

- Automated process steps reduce the workload for users

- Gentle processing of very large assemblies and components

- Reproducible rework results from the very first process

- Automatic contactless removal of residual solder

- Process verification via HRSoft 2

Product FeaturesProdukt-Features

Ersa Videos

Higher, faster, further! And also bigger: Ersa HR 600 XL – the ultimate solution for professional big board rework up to 24 x 24 inches. See the capabilities and flexibility of this exciting machine.

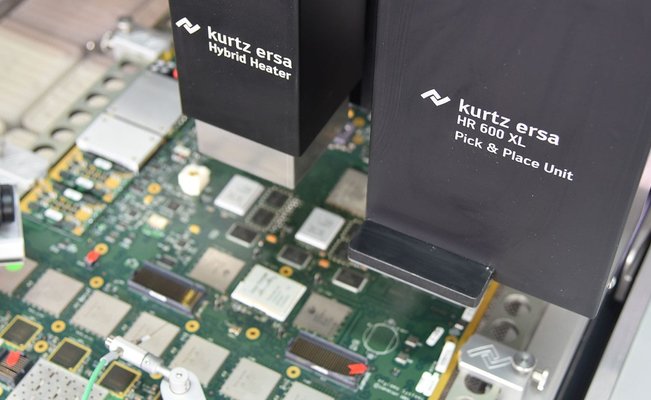

BIG-BGA-ReworkErsa Rework

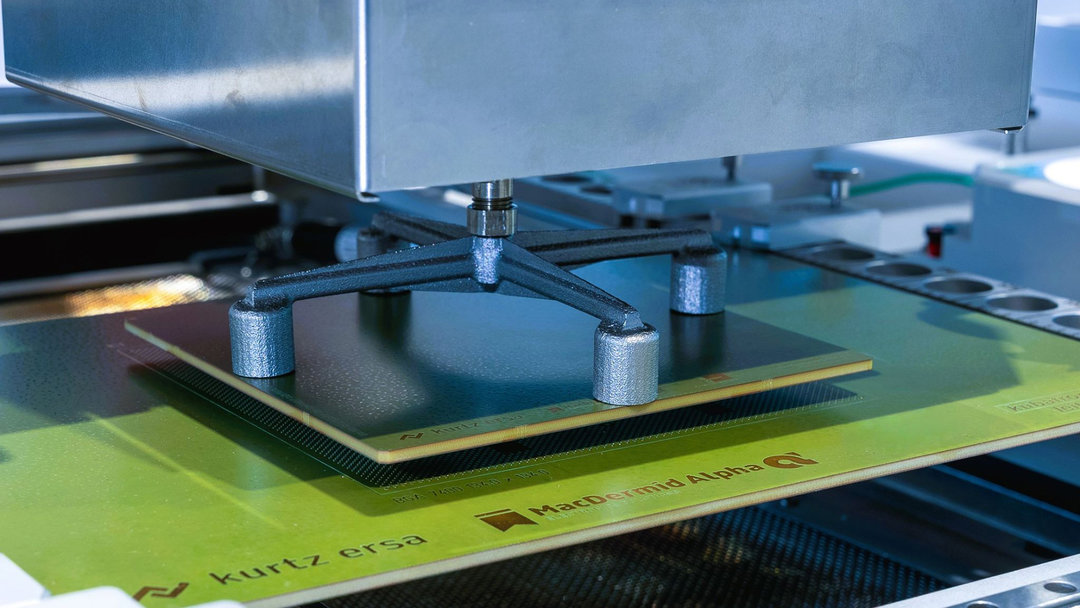

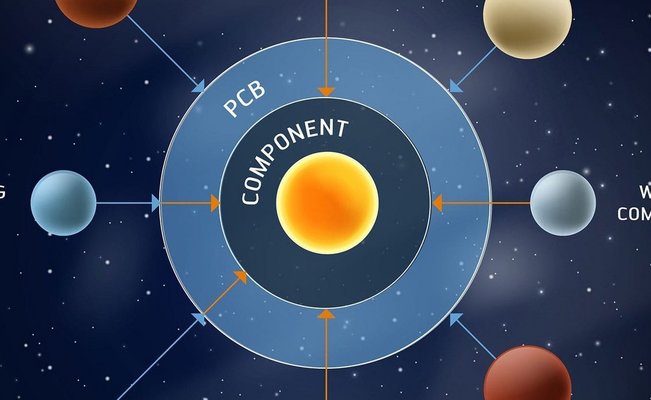

The HR 600 XL from Ersa offers everything you need for BIG BGA rework: the matrix preheating system gently and evenly heats large assemblies. A newly developed hybrid heating head with an effective area of 160 x 160 mm and up to 4,800 W of heating power provides the necessary energy coupling for soldering and desoldering processes. The AUTO SCAVENGER module removes residual solder without contact after a component has been desoldered. Together with the Kurtz Ersa experts from Additive Manufacturing, a new process for manufacturing individual grippers has been developed - these are specially adapted to the shape of the component and manufactured using metal 3D printing. Last but not least, the new "pin to pad" placement process uses image processing to enable the precise positioning of the new giant components.

Ersa Success StoriesHR 600 XL

HR 600 XLErsa Rework

Technical data

Recommended accessories

Order Information

Bitte wenden Sie sich direkt an Ihr Ersa Team!